電源の過電流保護に関する基礎

2022年4月5日、Bruce Rose著 - 7分の閲読

電源の過電流動作

私たちはエンジニアとして常日頃から「もしも」の事態を想定し、可能な限り多くのアプリケーション条件下で当社の設計が機能することを保証しています。当社の設計が正しく機能しない状況では、少なくとも当社の製品が損傷したり、他の製品を損傷させたりすることは回避しなければなりません。電源に関して多く抱かれる懸念の一つに、「当社の電源からの出力負荷電流が電源の電流定格を超えたらどうなるか」というものがあります。この記事では、定格負荷を超えた場合に電源設計で採用される一般的な方法について説明します。

最適な電源

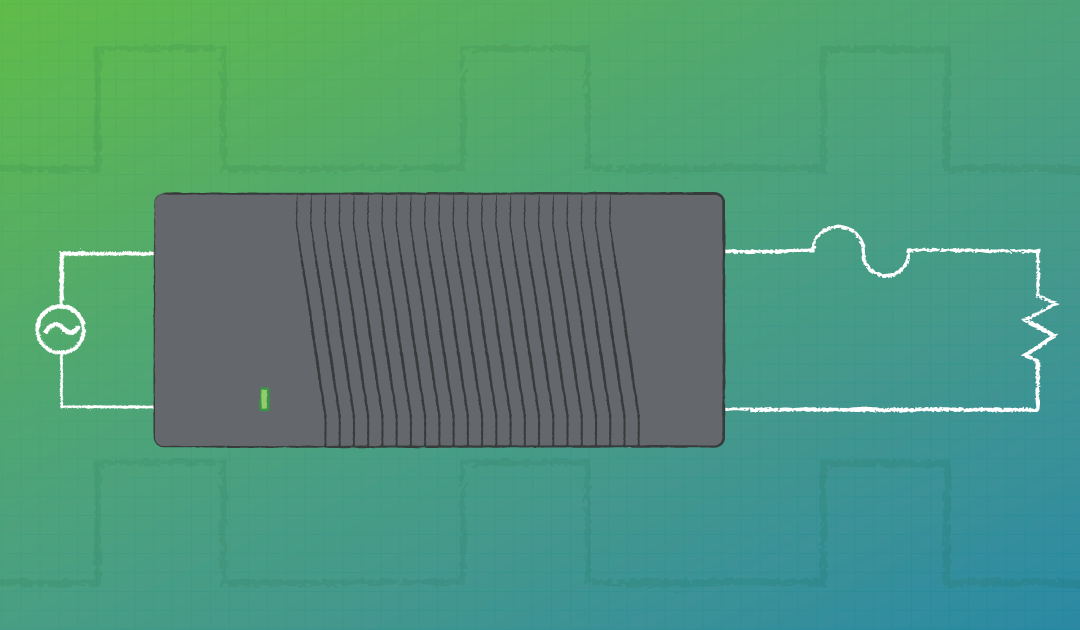

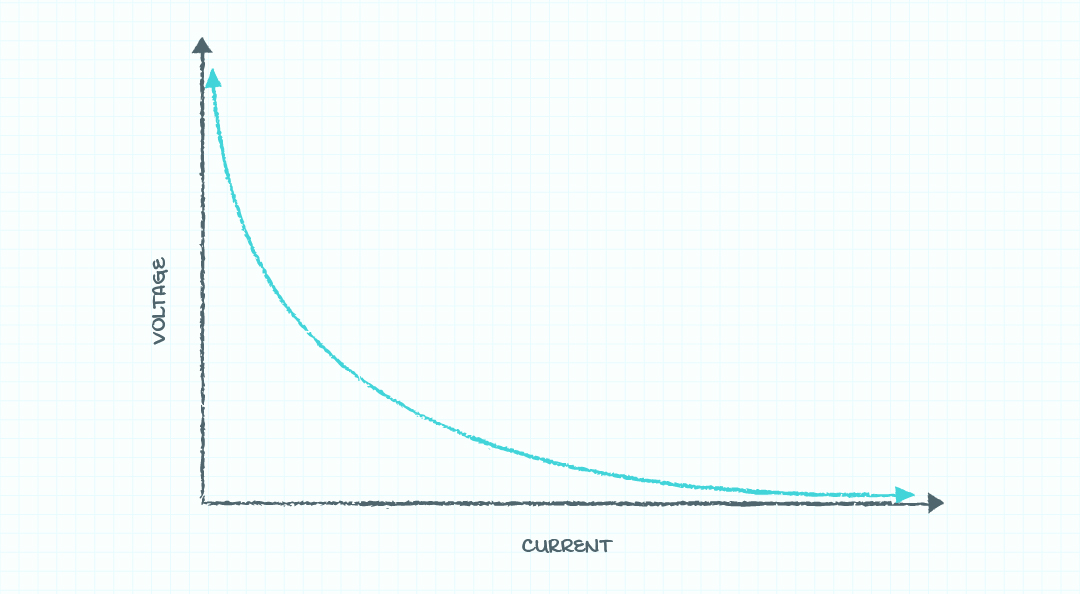

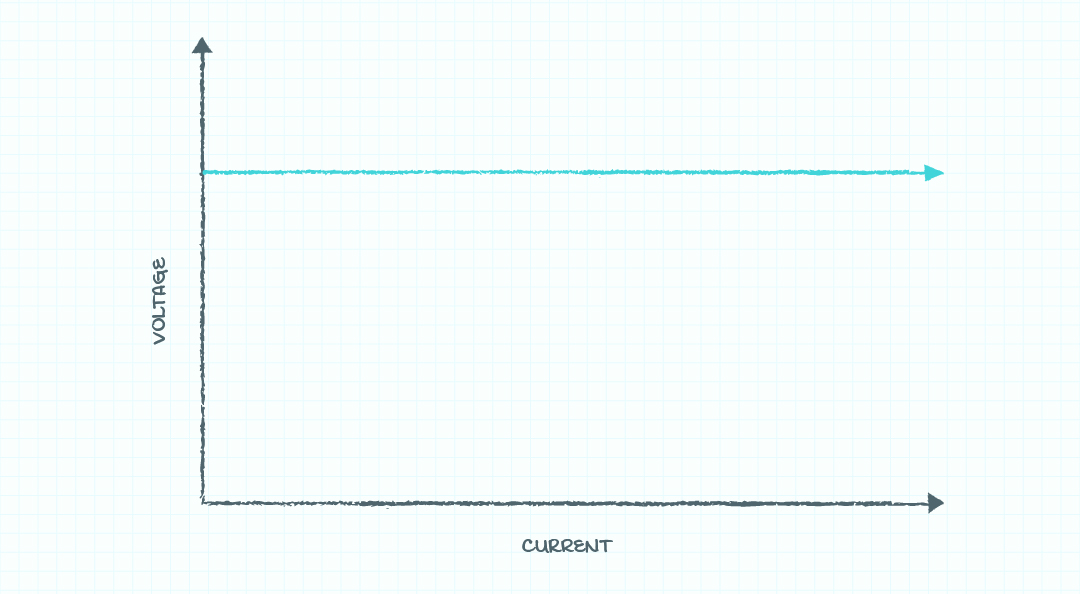

私たちがよく「電源」と呼ぶものは、実際のところは「電圧電源」のことを指しています。この2つの設計の違いは、理想的な「電源」では、負荷電圧や負荷電流に関係なく、負荷に一定の電力を供給します(図1)。また、理想的な電圧電源は、負荷電流に関係なく負荷に一定の電圧を供給します(図2)。こうした理想的な電圧電源を設計したり、作ったり、購入することは不可能です。なぜなら、理想的な電圧電源は、負荷に対して無制限の電流(そして電力)を供給するものであるからです。電源ではなく、電圧電源について私たちは議論していると述べましたが、ここでの議論では「電源」という用語を一般的に使用(誤用かもしれませんが)し続けていきます。

電源の電流制限

上述のように、すべての電源は何らかの形の電流制限を持ち、ほとんどの場合、電源は制御され、非破壊的です。この議論では、負荷が過大な電流を要求し、そうでなければ電源装置を損傷するような場合に、電源を保護するために、電源からの出力電流を制限することに焦点を当てていきます。入力電流の制限は多くの場合、入力導体の一方または両方と直列のヒューズの形態の電源に実装されています。この電流の制限は、上流電源および導体を保護するためのものです。入力ヒューズが切れてしまうほど高い入力電流が流れた場合、入力ヒューズのある電源はすでに損傷していると考えられます。一部のアプリケーションでは、バッテリーの充電など、適切に動作するために厳密に制御された電流制限が必要です。厳密に制御された電流制限が必要な場合は、電源のベンダーと協議する必要があります。ほとんどの電源では、電源の損傷を防ぐためだけにかけている緩い電流制限しかありません。電源からの出力電流を制限するいくつかの一般的な方法には、ヒューズ電流の制限、定電流制限、フォールドバック電流制限、ハイカップ電流制限などがあります。

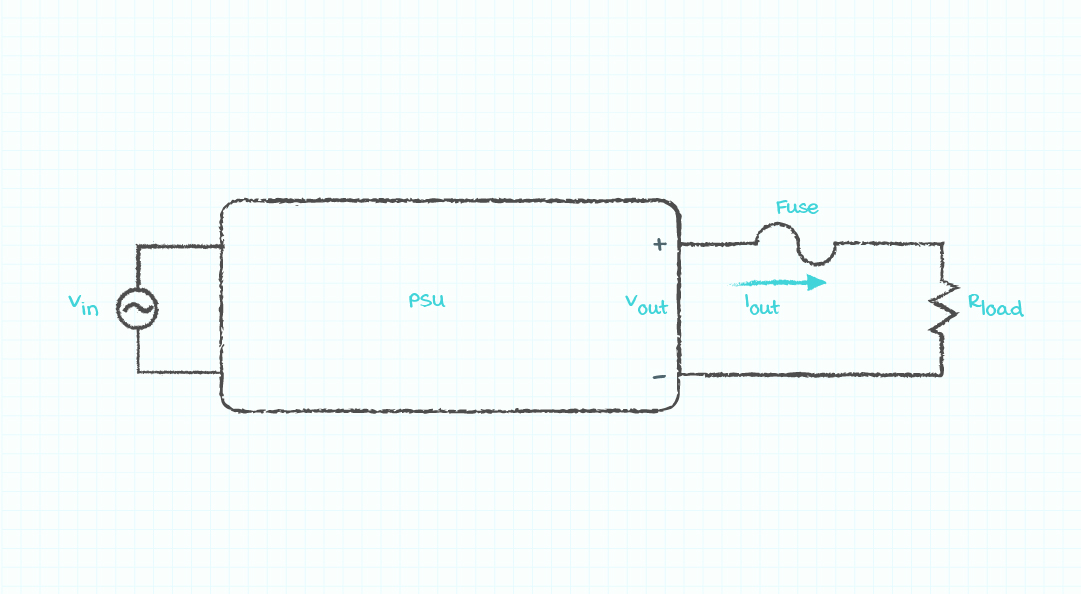

ヒューズ電流制限

電源出力電流制限の最も簡単な形態は、電源の出力端子と直列にヒューズを配置することです(図3)。この方法は効果的ですが、過度の負荷電流(すなわち、電源の出力端子またはプラグの短絡)を比較的容易に引き込んでしまい、ヒューズが飛んでしまうことがあるため、電源ではあまり採用されていません。また、電源の出力電流制限の機能により、過大な負荷電流による内部半導体部品への損傷を防止します。内部半導体を保護するのには十分な速さで飛ぶが、モータが起動したり、負荷コンデンサが充電されているときには飛ばないヒューズを選択することは難しい場合があります。ヒューズは導体を保護するのにはうまく機能しますが、半導体を保護するためにはそれほどよく機能しません。

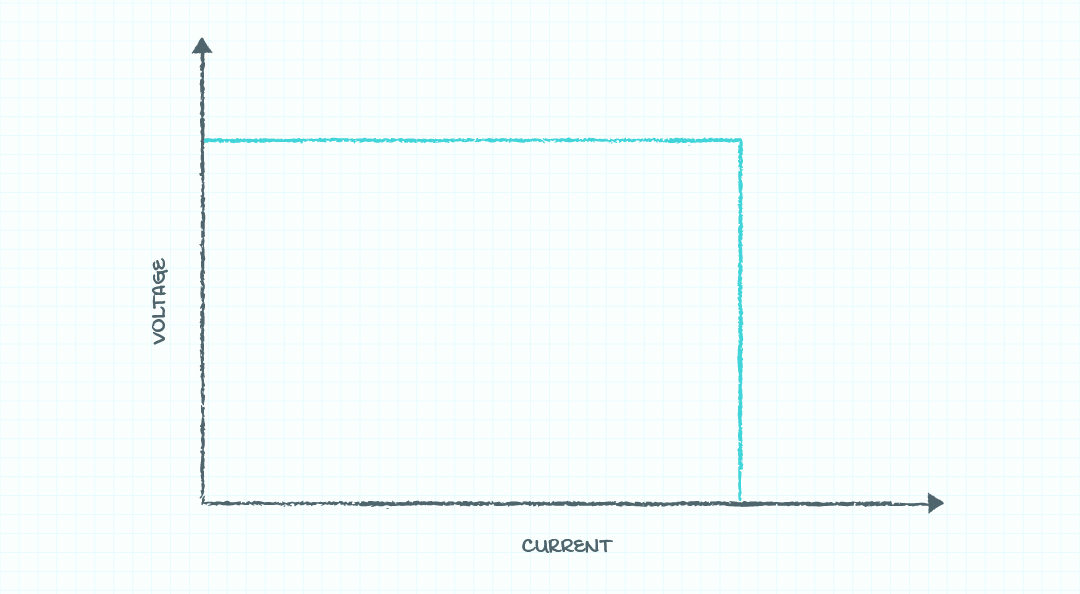

定電流の制限

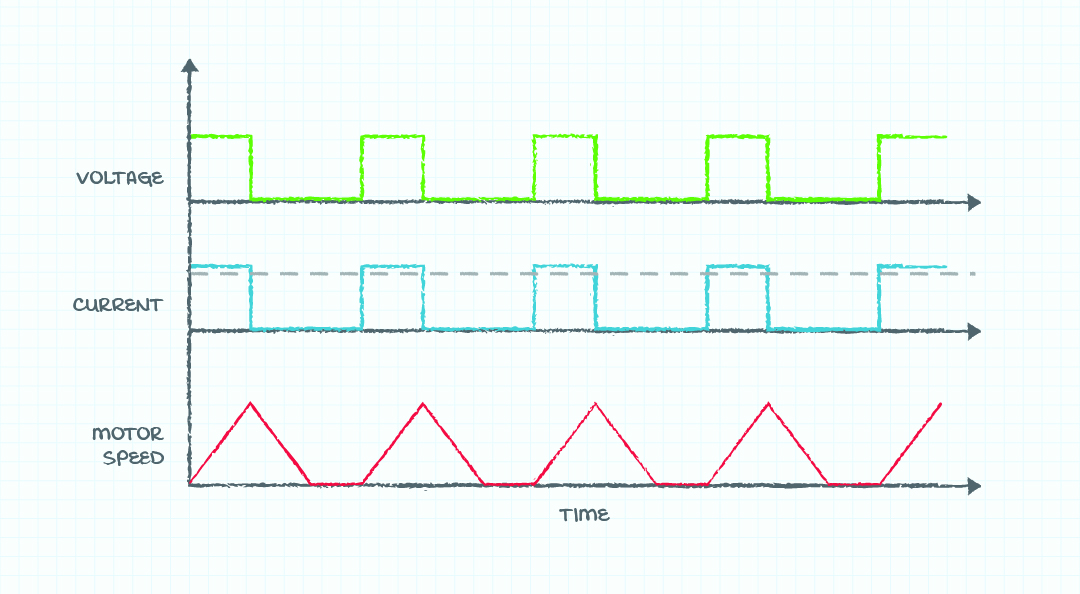

電源からの出力電流を制限するために実装されている一般的な方法は、最大出力電流を維持しながら、出力電流を監視し、電流制限に達したときに出力電圧を減少させることです(図4)。この実装では、電流制限中の出力電圧は、電流制限動作中の負荷によって提示されるインピーダンスに依存します。この電流制限の方法は比較的簡単に実装できますが、電流制限動作中に電源が最大電流で動作するため、出力電流経路のコンポーネントにストレスがかかります。この電流制限のバージョンは、モータの起動時やコンデンサ充電時のバイパスなど、負荷が過電流の短いバーストを引き込む場合に最適な選択となります。電源が電流制限モードになっていることに気付かないユーザーは、電源が電流制限モードで動作しているときに、出力電圧がデータシートで指定されたレベルよりも低いため、電源が正しく動作していないと思ってしまう可能性があります。

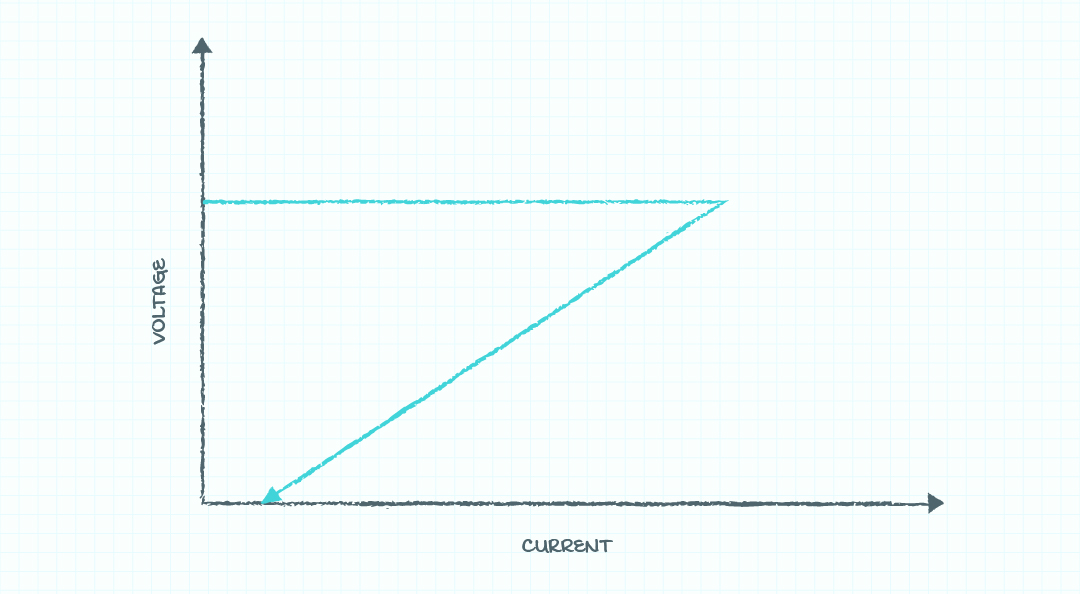

フォールドバック電流の制限

定電流の制限および上述におけるコンポーネントのストレスに関する問題に対処するために、一部の電源はフォールドバック電流制限で設計されています。この実装は、ユーザーにとって紛らわしくなる場合があります。フォールドバック電流制限電源では、最大出力電流が検出された後、出力電圧と出力電流の両方が減少します(図5)。フォールドバック電流制限電源の標準的な動作は存在しないため、ユーザーは選択した電源がどのように動作するかを理解するためにデータシートを読む必要があります。この電源出力電流制限の方法は、負荷がモータ起動時や入力バイパスデカップリングコンデンサを大量に充電している場合に問題が発生することがあります。電源装置が電流制限モードにあり、ユーザーが電源装置が適切な出力電圧または電流を生成しない理由を理解しようとしている場合、このフォールドバック動作はユーザーを混乱させてしまう可能性があります。

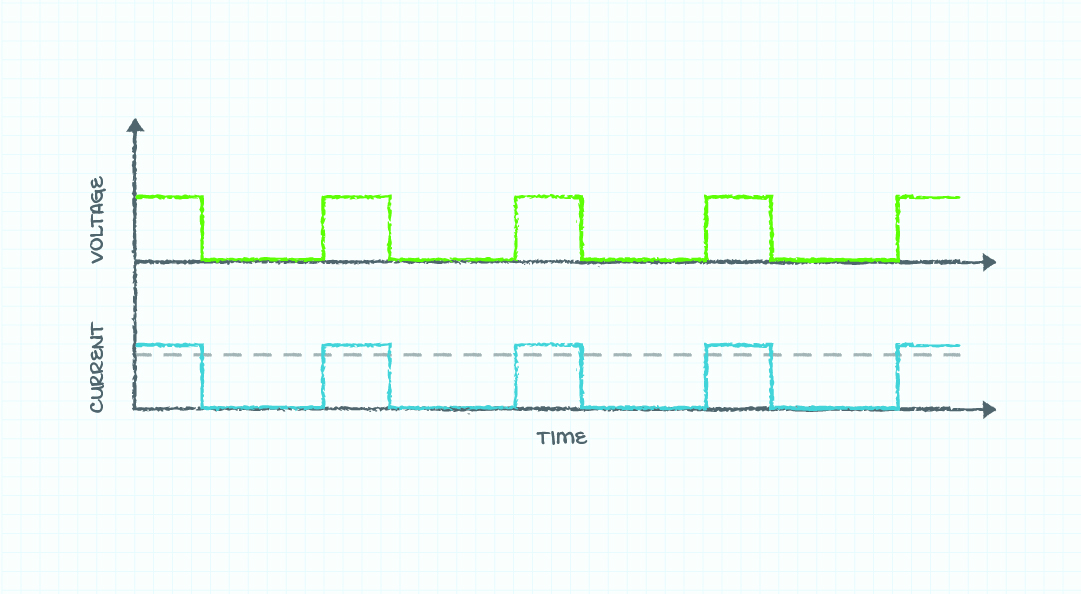

ヒカップモード電流制限

おそらく、電源で現在採用されている電流制限の最も一般的な実装は、ヒカップモードとして知られているものです。この過電流保護のモードは、この考察で前述したヒューズ保護のアクティブバージョンとして考えることができます。ヒカップモードの電流制限保護では、過電流状態が検出されると電源の出力電圧が停止します。指定された待機時間が経過すると、電源の出力電圧が再確立されます。過電流状態がまだ存在する場合、電源はシャットダウンと待機プロセスを繰り返します。過電流状態がなくなった場合、電源は通常モードで動作を継続します(図6)。

ヒカップモードによる過電流保護は、電圧レギュレータのコントローラチップへの実装が容易で、電源出力電力パスの部品への過電流ストレスを最小限に抑えることができます。ヒカップモードの過電流保護は、モータ起動時の負荷や、入力フィルタコンデンサのバンクが大きい場合に問題となることがあります。モータ負荷のあるアプリケーションでは、電源がオンになっている間にモータが適切に始動しない場合、モータは電源の出力電圧のオフ時に減速し、次のヒカップサイクル中に再び始動しません。この状態では、電源の出力電圧ではオフ時となっているため、モータが始動することはありません(図7)。

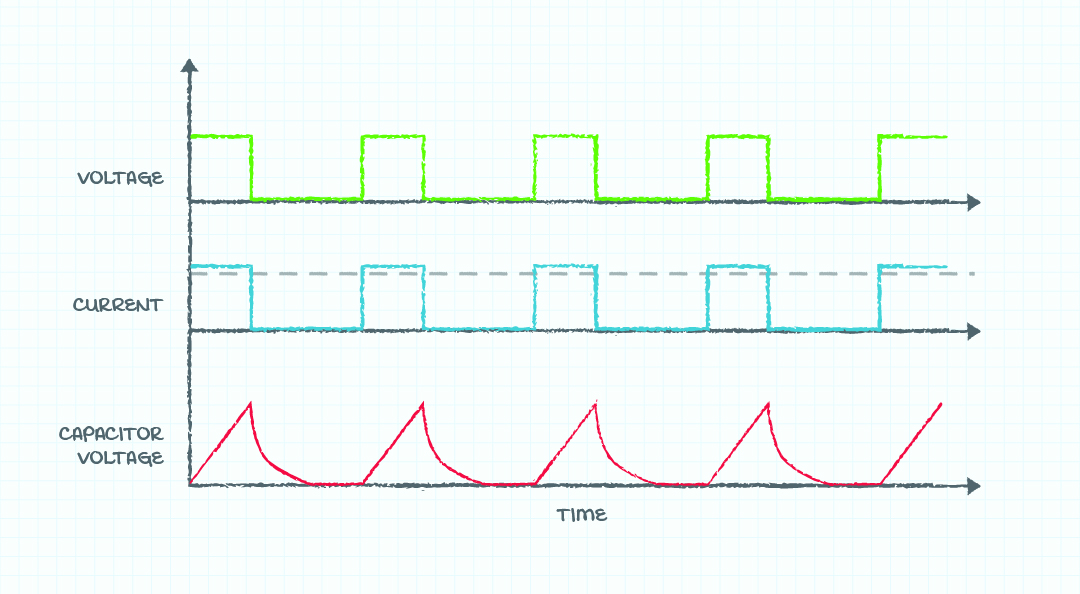

負荷が入力フィルタコンデンサで大きな値で、負荷電流も存在する場合は、同様の問題が発生することがあります。電源の出力電圧が最初に放電したコンデンサに印加されると、コンデンサが消費する電流が大きくなり、電源が過電流動作になり得ます。電源オフ時に、コンデンサ以外に負荷電流が存在する場合、負荷電流は、電源オフ時にその負荷電流によってコンデンサが十分に放電され、コンデンサが電源出力電圧まで充電されることができません(図8)。

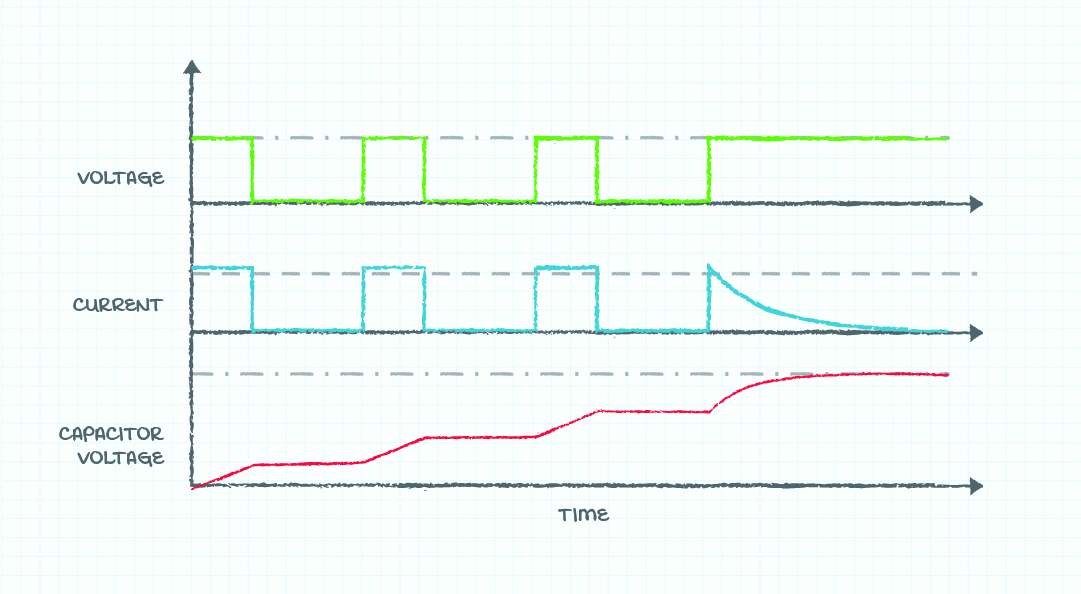

負荷電流が十分に低い(または存在しない)場合、電源出力電圧のパルスによって、コンデンサは階段状に充電され、電源と負荷は最初の始動遅延後に適切に動作します(図9)。

自分の仕様を知る

電源の出力電流制限はすべての電源に存在します。一般に、ユーザーは、使用する電源装置でどのような種類の電流制限が使用されているか、したがって、出力過電流の状況下で電源装置がどのように動作するかを理解することが有益です。DMM(デジタルマルチメーター)のみで電源の出力電圧を観察すると、出力電圧が電源データシートで指定されている値でないときに何が起きているかについて、ユーザーは混乱することがあります。

この記事またはトピックに関するコメントを今後当社が取り上げるべきだと思いますか?

powerblog@cui.comにメールでご連絡ください。